Choosing the right restorative material isn’t just about durability; esthetics play a crucial role in patient satisfaction and case acceptance. When natural teeth lose their contours from wear, they appear flat and lack the vitality of a youthful smile. Recreating the subtle details—the mamelons, the incisal translucency, and the gentle undulations of the labial surface—is the key to a successful outcome. This is where digital dentistry truly excels. It provides the tools to move beyond simple repairs and into the realm of artistry, allowing us to meticulously redesign a smile. We'll examine how to restore 'digital flat teeth' by focusing on the esthetic principles that define a natural look.

Why Esthetics Matter in Digital Denture Teeth

Why Esthetics Matter in Digital Denture Teeth

Choosing the right teeth for dentures isn’t just about durability. Digital denture teeth esthetics play a crucial role in patient satisfaction and treatment outcomes. As the dental industry shifts toward fully digital workflows, understanding the esthetic elements of denture teeth becomes increasingly important.

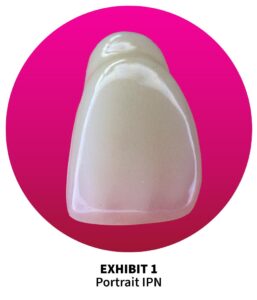

One of the most important attributes of any denture is the appearance of the teeth. In the American market, certain esthetic norms have emerged over time. Among all teeth, the maxillary central incisors are considered the most visually significant — whether natural or artificial. Manufacturers typically mold denture tooth shade guides from a maxillary central incisor.

In Exhibit 1, you’ll see a maxillary central from the premanufactured Portrait IPN line — mold 22E in shade A2. Although esthetics are always somewhat subjective, North American preferences tend to focus on five core features. All of these are present in the Portrait IPN tooth.

-

Translucent incisal edge: The incisal edge must be translucent. Ideally, this translucency should wrap around the mesial and distal corners and extend into the interproximal spaces.

-

Mamelons: Sometimes called “lobes,” mamelons should be subtly visible. These downward-protruding structures add natural irregularity and depth.

-

Neck contrast: The neck of the tooth should appear darker — in color science, this means a lower value.

-

Surface translucency: A translucent labial-buccal surface allows light to pass through to underlying layers, enhancing depth.

-

Labial surface contour: For central anteriors, the labial surface must have a slight undulation. This shape helps reflect light naturally, like ripples on a pond.

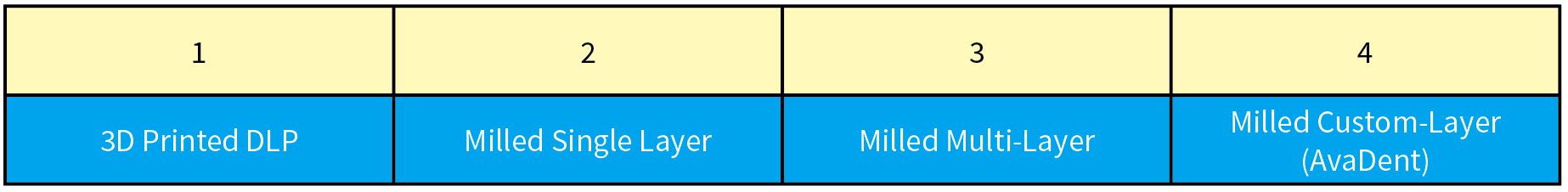

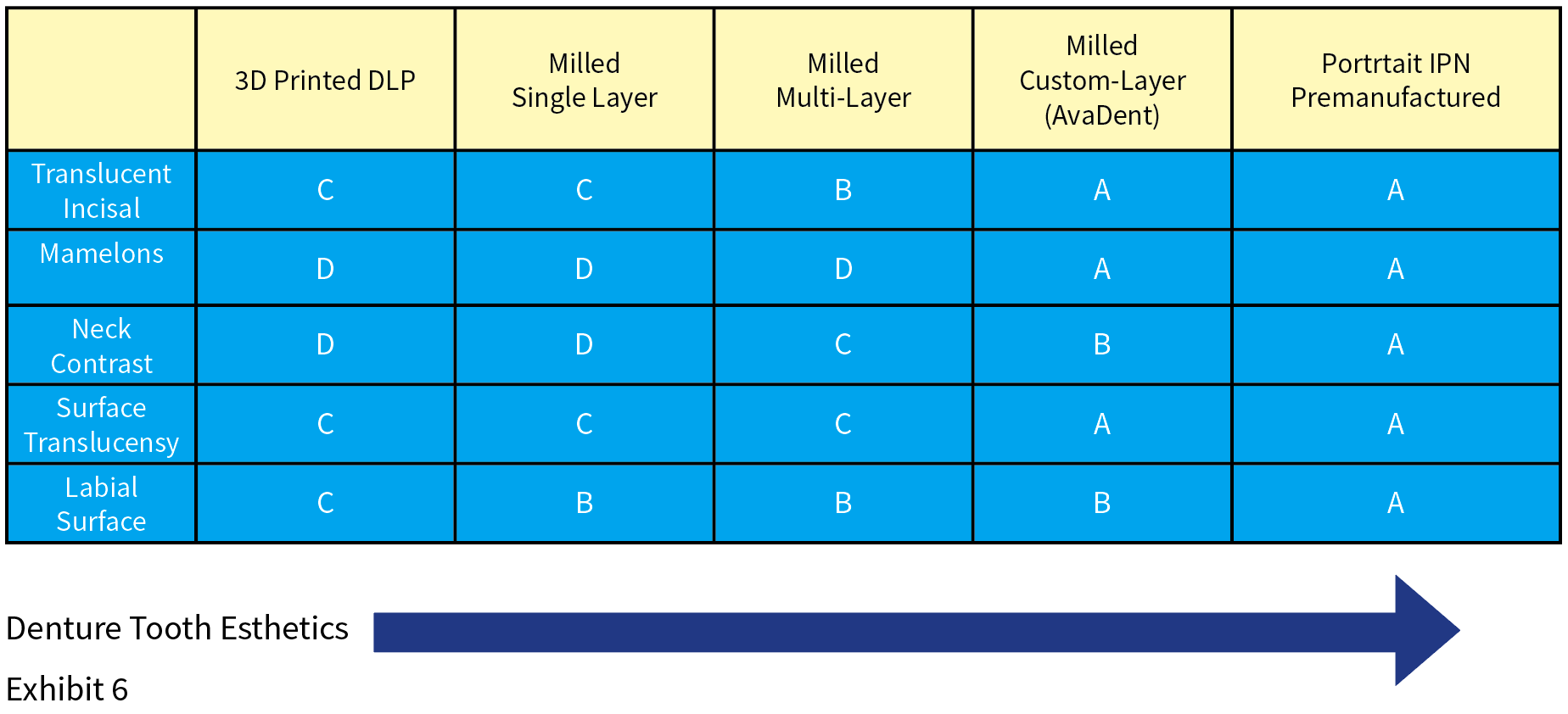

Now let’s look at teeth esthetics in a variety of digital dentures. I have established four categories so you can more clearly understand the differences (Exhibit 2).

Exhibit 2

1. 3D-Printed DLP Denture Teeth

1. 3D-Printed DLP Denture Teeth

The first category is 3D-printed teeth using digital light processing (DLP) — the most common 3D printing method. 3D printers use a single material to produce these teeth.. Manufacturers attempt to balance opacity and translucency, aiming for a translucent incisal edge and a more opaque body.

Most resins can achieve that horizontal translucency. However, they fail to produce the natural look that comes from translucency wrapping around the mesial and distal corners. Because manufacturers form the teeth from a uniform material, mamelons do not exist. While some techniques attempt to simulate them by carving vertical grooves into the labial surface, the effect is minimal and not convincing.

3D-printed teeth also lack a distinct neck contrast since there is no shading variation in the material. Sometimes, the denture base gives the illusion of a darker neck, but that effect remains inconsistent and less effective than with high-end esthetic denture teeth.

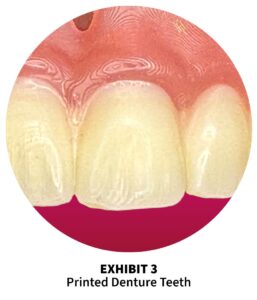

Surface translucency in these teeth comes from the base material itself. Without a second contrasting layer, however, the result is a flat, monochromatic look with little depth. The labial surface quality depends heavily on how it’s finished. Even if the digital file includes natural contours, aggressive polishing during finishing can flatten the anatomy. Because 3D printing occurs in layers, this process often results in a surface that resemble a topographical map unless refinished carefully — as shown in Exhibit 3.

2. Milled Single-Layer Denture Teeth

2. Milled Single-Layer Denture Teeth

The second category is milled single-layer teeth, where the teeth and base are milled separately and then bonded. Milling produces dimensionally accurate results, but in terms of esthetics, the approach has pros and cons.

Translucency depends on the properties of the single-layer PMMA puck. Like 3D printing, achieving an esthetic balance requires manufacturers to compromise between incisal translucency and body opacity. And like 3D-printed teeth, this translucency remains horizontal only, with no extension into the mesial or distal corners.

In terms of mamelons, neck contrast, and surface translucency, milled single-layer teeth perform no better than their printed counterparts. However, the labial surface quality tends to be slightly better. The smoother raw finish requires less manual adjustment. Still, it doesn’t match the finish of injection-molded denture teeth formed in steel molds.

3. Milled Multi-Layer Denture Teeth

3. Milled Multi-Layer Denture Teeth

In this third category, technicians mill the teeth from a multi-layered puck made of 8 to 16 stacked layers. These layers transition from translucent to opaque horizontally, similar to sliced cheese. This design improves incisal edge appearance slightly compared to single-layer pucks.

By positioning anterior teeth precisely within the puck, technicians can optimize where the translucent layers fall. However, translucency still does not curve up into the corners or interproximal areas. Laterals, being slightly raised from centrals, may not align optimally with the puck’s translucent zone.

Mamelons are still absent in this technique. However, neck contrast improves due to the puck's darker lower layers. Despite this, the effect is again limited to a horizontal gradient. Like the prior categories, surface translucency lacks true depth and appears flat.

What Are Digital Dentures?

Let's start with the basics. Digital dentures are prosthetic teeth created using a fully computerized workflow. This process involves digital scanners, specialized design software, and advanced manufacturing machines that either carve the denture from a solid block (milling) or build it layer by layer (3D printing). Unlike traditional methods that rely on manual processes and physical impressions, the digital approach is engineered for precision. The result is a prosthesis that is designed to be more exact, fabricated faster, and often feels significantly more comfortable for the patient. This technology represents a major step forward, giving clinicians and technicians incredible control over the final outcome and delivering a product that truly fits the patient's unique anatomy with predictable results.

The Digital Denture Workflow Explained

Shifting from a traditional to a digital denture workflow can feel like a big change, but the process itself is logical and streamlined. It breaks down into three main phases: scanning, designing, and manufacturing. Each step replaces a manual, often time-consuming task with a more accurate and efficient digital equivalent. This not only speeds up the entire process but also introduces a level of precision that is difficult to achieve by hand. By embracing this workflow, dental professionals can reduce the chance of errors, minimize the need for adjustments, and ultimately provide a better experience and final product for their patients. Let's walk through what each of these steps involves.

Step 1: Acquiring a 3D Scan

Everything begins with creating a detailed 3D picture of the patient's mouth. This digital impression is the foundation for the entire process, and there are a few ways to capture it. You can scan directly inside the patient's mouth using an intraoral scanner, which is fast and comfortable for the patient. Alternatively, you can take a traditional physical impression and then scan it with a desktop scanner. It's even possible to scan a patient's existing denture to create a precise copy or an improved version. Whichever method you choose, the goal is to generate a highly accurate data set that will serve as the blueprint for the new prosthesis.

Step 2: Designing with CAD Software

Once the 3D scan is complete, it's imported into computer-aided design (CAD) software. This is where the artistry and technical skill of the dental technician come to life in a digital environment. The software provides powerful tools to design every aspect of the denture, from the shape and size of the teeth to the contours of the gingiva. The technician can ensure a perfect fit, establish proper occlusion, and create a natural-looking smile that complements the patient's facial features. This digital design phase allows for incredible customization and verification before any physical product is made, ensuring the final result is exactly what you and your patient envisioned.

Step 3: Production and Finishing

With the design finalized, it's time for manufacturing. The digital file is sent to either a milling machine or a 3D printer. Some workflows include creating a "try-in" version of the denture first. This is a simple, monolithic prototype that allows you to verify the fit, bite, and overall look in the patient's mouth before committing to the final prosthesis. This step is invaluable for confirming the accuracy of the design and making any necessary adjustments. Once everything is approved, the final, high-quality denture is fabricated, finished, and polished, ready for delivery to the patient.

Manufacturing Methods: Milled vs. 3D-Printed

When it comes to producing digital dentures, milling and 3D printing are the two primary methods, and they have distinct differences, especially concerning esthetics. The most common 3D printing method, DLP, typically uses a single resin material to form the teeth. While it can achieve some translucency at the incisal edge, the uniform material often results in a less natural look that lacks depth and character. Milled teeth can be produced from single-layer pucks, but they face similar challenges in balancing opacity and translucency. As we've discussed, achieving truly lifelike esthetics requires more than just a single shade. It demands the subtle interplay of color and light that only a layered, thoughtfully constructed tooth can provide, which is why the choice of material and manufacturing process is so critical.

The Clinical Advantages of Going Digital

Adopting a digital denture workflow isn't just about keeping up with technology; it's about delivering tangible clinical benefits that enhance patient care and improve practice efficiency. From a superior fit that reduces chair time to materials that promote better oral health, the advantages are clear and compelling. Digital methods provide a level of accuracy and consistency that traditional techniques simply can't match. This precision translates directly into better clinical outcomes and higher patient satisfaction. Furthermore, the efficiency of the digital process streamlines everything from impression-taking to final delivery, allowing you to treat more patients effectively. Let's explore some of the most significant clinical advantages you can expect when you make the switch.

Exceptional Fit and Patient Comfort

One of the most immediate benefits of digital dentures is the incredible precision of the fit. Digital scanning is exceptionally accurate, capturing the fine details of the patient's oral structures without the distortion that can occur with physical impression materials. This accuracy translates directly into a denture that fits better and feels more comfortable from the very first insertion. For clinicians, this means fewer post-delivery adjustments and less chair time spent on fine-tuning. For patients, it means a more secure and comfortable prosthesis that allows them to eat, speak, and smile with renewed confidence right away.

Increased Strength and Longevity

The way digital dentures are made can also make them significantly stronger than their traditional counterparts. In fact, prostheses that are milled from a solid block of material can be up to eight times stronger than conventional dentures. At AvaDent, our monolithic dentures are milled from a pre-shrunk, high-density puck of PMMA. This process eliminates the weak point created when bonding individual teeth to a denture base, resulting in a single, solid unit that is incredibly durable and resistant to fractures. This inherent strength means a longer-lasting prosthesis and fewer repairs for your patients.

A Faster, More Efficient Process

Time is a valuable resource for both you and your patients. The digital workflow is designed for efficiency, significantly reducing the number of appointments required to complete a case. With traditional methods, the process can stretch over five or more visits. A digital workflow can often condense this into just two or three appointments. This streamlined process means patients spend less time in the dental chair, and your practice can operate more productively. It’s a win-win that improves the patient experience while allowing you to manage your schedule more effectively.

The Power of a Permanent Digital Record

Imagine a patient loses or breaks their denture. With traditional methods, you'd have to start the entire process over from scratch. With digital dentures, you have a permanent digital file saved indefinitely. If a replacement is ever needed, a new denture can be fabricated directly from the saved design without requiring the patient to come in for new impressions. This "digital twin" provides incredible peace of mind and convenience. It’s a powerful safety net that ensures a perfect replacement is just a click away, saving time, money, and stress for both the patient and your practice.

Hygienic Materials for Better Patient Health

Patient health is always the top priority, and the materials used in digital dentures contribute to better oral hygiene. The high-density PMMA used in AvaDent's milled dentures is non-porous, which makes it highly resistant to staining and bacteria buildup. Some advanced materials have even been shown to reduce bacteria on the surface by 99.9% in lab tests. This less-porous surface is easier for patients to clean and helps prevent the odors and irritation that can be associated with conventional acrylic dentures. By providing a more hygienic prosthesis, you are directly contributing to your patient's long-term oral and overall health.

4. AvaDent Milled Custom-Layer Denture Teeth

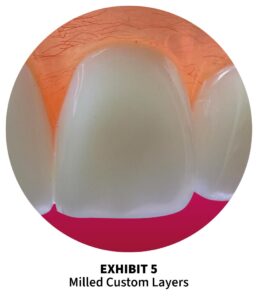

AvaDent’s milled custom-layer teeth make up the final category, which take a monolithic approach — digitally layering custom dentin and enamel for each individual tooth. This method addresses nearly all the limitations of the other three.

Technicians mill the dentin layer with natural-looking mamelons first. They then apply a translucent enamel layer over the top, covering the entire labial-buccal surface. The result is a level of incisal translucency that rivals premium denture teeth.

AvaDent’s AI-driven software automatically adjusts mamelon geometry based on tooth size, ensuring visual consistency across molds. Translucency wraps around the mesial and distal edges, just like in the best premanufactured teeth.

The neck contrast comes from the base material visible through the translucent enamel. While not as dramatic as that seen in the Portrait IPN tooth — which uses a specific darker neck layer — it still delivers esthetically pleasing results.

Surface translucency and the labial finish are where this approach truly shines. Unlike printed or single-puck milled teeth, AvaDent’s surface is already layered for depth and light reflection. Although technicians must polish the surface to remove milling marks, the final result closely mimics premium, carded denture teeth.

Comparing the Esthetic Results

As summarized in Exhibit 6, each category presents tradeoffs. But AvaDent’s milled custom-layer approach earns the highest marks for digital denture teeth esthetics — closely matching the visual qualities of Portrait IPN pre-manufactured teeth.

Addressing Flat Teeth in Natural Dentition

While we've focused on the esthetics of denture teeth, these principles are just as critical when treating natural dentition. Patients often present with flattened or worn teeth, which impacts both their smile's appearance and their oral function. Understanding the root causes of this occlusal wear is the first step toward providing effective, esthetically pleasing restorations. This wear doesn't happen overnight; it's a gradual process that can stem from a variety of factors, from subconscious habits to dietary choices. By identifying the cause, you can restore the damage and help your patients prevent further issues, preserving their natural smile for years to come.

Common Causes of Occlusal Wear

When a patient comes in with noticeably flat teeth, there are usually two main culprits to investigate: mechanical wear and chemical erosion. Mechanical wear is often caused by bruxism, the involuntary grinding or clenching of teeth, which can exert incredible force on the occlusal surfaces. On the other hand, chemical erosion is typically linked to diet, where acidic foods and beverages soften the enamel, making it more susceptible to wear. Both pathways lead to a loss of natural tooth anatomy, resulting in a flattened, aged appearance and potential functional problems. Pinpointing the primary cause is critical for developing a comprehensive treatment plan that addresses the existing damage and mitigates future wear.

Bruxism and Its Effects

Bruxism is a common condition that can cause significant damage over time. Many patients who grind their teeth, especially during sleep, are completely unaware of the habit until they notice symptoms like jaw pain, headaches, or visible tooth wear. This constant grinding abrades the enamel, gradually flattening the cusps of the molars and incisal edges of the anteriors. The result is a loss of vertical dimension and a less youthful, less defined smile. For these patients, a night guard is often a crucial first step in prevention, but addressing the existing damage requires restorative work that can rebuild the lost tooth structure and re-establish proper function.

Dietary and Acid Erosion

What your patients eat and drink has a direct impact on their enamel. A diet high in acidic substances—like citrus fruits, sodas, and certain sports drinks—can lead to significant chemical erosion. This acid attacks and demineralizes the tooth surface, softening the enamel and making it easy to wear away during normal chewing. Over time, this process can completely erase the natural contours of the teeth, leaving them flat and featureless. Educating patients on the effects of an acidic diet is a key part of preventive care, as simple changes can make a big difference in preserving their enamel and avoiding the need for extensive restorative procedures in the future.

Restorative Solutions for Worn Teeth

Once occlusal wear has occurred, the goal is to restore both form and function. For severely flattened teeth, full-coverage dental crowns are often the best solution, as they can completely rebuild the tooth's anatomy, providing structural support and a highly esthetic result. In other cases, more conservative options like onlays or veneers might be appropriate. Regardless of the specific restoration, the key is to recreate the natural contours and cusps that were lost. This not only improves the appearance of the smile but also restores the proper mechanics of chewing, ensuring the patient can function comfortably. Digital design and milling technologies have made it easier than ever to create precise, lifelike restorations that blend seamlessly with the remaining dentition.

Preventive Care and Patient Education

Restoring worn teeth is only half the battle; preventing recurrence is just as important. This is where patient education becomes your most powerful tool. Taking the time to explain the "why" behind their occlusal wear—whether it's bruxism, diet, or a combination of factors—empowers patients to take an active role in their oral health. For those with bruxism, discussing the benefits of a custom occlusal guard can be a game-changer. For others, providing simple dietary counseling about reducing acidic food and drink consumption can halt the progression of erosion. Regular dental check-ups are also essential, as they allow you to spot the early signs of wear and intervene before significant damage occurs.

Practical Considerations for Your Practice

Choosing the right restorative approach involves more than just clinical judgment; it also requires balancing practical factors like lab turnaround time, material costs, and long-term durability. As you integrate more digital solutions into your practice, you'll find that these workflows can offer greater efficiency and predictability. However, it's important to understand the nuances of different digital systems and materials to make the best choices for your patients and your practice. From selecting the right shades to ensuring a comfortable fit, every detail contributes to a successful outcome. Thinking through these practical considerations ahead of time will help you streamline your process and consistently deliver high-quality care.

Lab Time, Warranties, and Cost

When you're planning a restorative case, the conversation around time and cost is unavoidable. Different materials and techniques come with varying price points and production timelines. For instance, milled custom-layer solutions, like those we've perfected at AvaDent, provide superior esthetics and strength, but the initial investment may be higher than for single-layer or 3D-printed options. It's important to weigh this against the long-term value, including durability and patient satisfaction. Digital workflows can often reduce chair time and lab time, creating efficiencies that benefit both you and your patient. Always consider the warranty and support offered by your lab or manufacturing partner, as this provides peace of mind and protects your investment.

Customization Options: Tooth and Gingiva Shades

Achieving a truly natural-looking restoration hinges on customization. The ability to precisely match tooth and gingiva shades is essential for creating a result that patients will be happy to show off. This is another area where digital technology excels. Digital shade matching tools and advanced software allow for incredible accuracy, taking the guesswork out of shade selection. With systems like AvaDent's, you can specify custom layering of dentin and enamel, creating a depth and translucency that mimics natural teeth. This level of detail ensures that the final restoration blends seamlessly, whether you're treating a single tooth or a full arch, leading to higher case acceptance and greater patient satisfaction.

Patient Adaptation and Functionality

A beautiful restoration is only successful if the patient can adapt to it comfortably and use it effectively. Functionality is paramount. The fit of the final prosthesis or crown must be precise to ensure comfort, proper speech, and efficient chewing. This is where the accuracy of digital manufacturing truly shines. Because AvaDent's digital restorations are milled from monolithic materials, the fit is incredibly predictable, minimizing the need for frustrating and time-consuming adjustments. When patients can adapt quickly to their new teeth without discomfort or functional issues, their confidence soars, and they are more likely to be delighted with the outcome of their treatment.

How to Choose the Right Denture Teeth

Selecting denture teeth goes beyond durability or manufacturing method. Digital denture teeth esthetics can profoundly affect patient satisfaction. Studies show that patients are far more likely to accept dentures that mimic natural teeth in detail and translucency.

To learn how AvaDent’s innovations enhance esthetics and clinical outcomes, visit us at AvaDent.com.

All images were taken with an iPhone14 macro lens. Digital denture teeth esthetics

Frequently Asked Questions

Why do most 3D-printed and single-layer milled teeth look "flat" or unnatural? The flat appearance comes down to the material. Most 3D printing and single-layer milling methods use a single, uniform block of resin or PMMA. While manufacturers try to balance opacity and translucency, the material lacks the internal structure of a natural tooth. This results in a monochromatic look that can't replicate the subtle depth, mamelons, or the way light plays through different layers of enamel and dentin.

My patient has severely worn natural teeth. Can I use these same digital design principles to restore their smile? Absolutely. The esthetic principles for creating beautiful denture teeth are the same ones you'd use to restore natural dentition. When teeth are worn down from bruxism or erosion, digital design software gives you the tools to meticulously rebuild that lost anatomy. You can recreate the natural contours, incisal translucency, and surface texture, restoring not just the appearance but also the proper function of their bite.

Besides esthetics, what is the most significant clinical advantage of a milled monolithic denture? The biggest advantage is its incredible strength and durability. Traditional dentures bond separate teeth to a base, creating a potential weak point. A monolithic denture, like those from AvaDent, is milled from a single, solid puck of high-density PMMA. This process creates a unified prosthesis that is far more resistant to fractures and breakage, leading to a longer-lasting restoration and fewer repairs for your patient.

What exactly is a "digital twin" and why is it so valuable for my patients? A "digital twin" is the permanent digital file of the patient's final prosthesis that is stored indefinitely. Its value is a huge source of peace of mind. If a patient ever loses or breaks their denture, you can order an identical replacement using that saved file. There's no need for the patient to come back for new impressions or appointments. A perfect copy can be fabricated quickly, saving time, money, and stress for everyone involved.

How does AvaDent's custom-layering process create more realistic translucency? Our approach digitally mimics the structure of a natural tooth. We mill the inner dentin layer first, complete with lifelike mamelons. Then, we mill a translucent enamel layer over the top of it. This layered construction allows light to pass through the "enamel" and reflect off the "dentin" below, creating true-to-life depth and character. This process also allows the translucency to wrap realistically around the corners of the tooth, an effect that single-layer methods can't achieve.

Key Takeaways

- Focus on Lifelike Details for Superior Esthetics: To move beyond a flat, artificial look, prioritize recreating key anatomical details. This includes wrapping incisal translucency into the interproximal spaces, defining subtle mamelons, and sculpting natural labial contours.

- Choose a Manufacturing Process That Supports Layering: Not all digital denture methods are equal. To achieve true depth and avoid a monochromatic result, select a process like custom-layer milling that builds in translucency and color variation, rather than relying on a single block of material.

- Embrace Digital for a More Efficient Practice: A digital workflow streamlines the entire denture process, leading to fewer appointments and less chair time for adjustments. The result is a stronger, better-fitting prosthesis and a permanent digital file for easy replacements, improving both patient satisfaction and practice productivity.